Common Problems with iGaging EZ-View Scales

iGaging EZ-View DRO and their older predecessors, the iGaging DigiMag scales, have been the mainstay of hobby machine shops for almost a decade. Originally, iGaging marketed these scales for woodworking, but due to their attractive price point, remote readout display, and the ability to use them with TouchDRO, they have become quite popular with hobby machinists. The scales offer great value and reasonable performance, and when set up correctly, can work very reliably. Unfortunately, these scales have a few inherent issues and are sensitive to noise. As a result, a small percentage of TouchDRO users struggle with getting stable and reliable position readout. Most of the problems fail into a few common categories such as flickering last digit, momentary jumps, permanent jumps, resets, and climbing readout. Fortunately, most of these issues can be fixed or at least partially mitigated.

Many of the problems listed below can be caused or exaggerated by grounding and power supply issues. Refer to the Avoiding Common DRO Scale Problems page to rule these problems out.

iGaging EZ-View Principle of Operation

In order to better understand common iGaging EZ-View problems and failure modes, it's important to have a basic understanding of how these scales read the position and communicate it with the display unit or a TouchDRO adapter.

The scale consists of a metal frame with attached narrow circuit board material (such as fiberglas, phenolic, or even glass) on which a special [precise] encoder pattern is etched. While in practice this is not strictly the case, you can think of this as a series of equally spaced rectangular pads. Inside the reading head, there is another PCB that has similar rectangular pads that are connected to the scale's processor. The spacing between the sensor PCB pads is such that at any given time each of them has a different amount of overlap with an encoder pads, similar to how a Vernier scale works, in fact. The scale's processor can then measure the capacitance at each of these pads to detect minute movement or absolute positions, depending on the scale. As the scale moves, the processor keeps track of the movement and periodically sends it to the display.

To send the position to the display, scale's reading head uses a binary synchronous protocol. In plain english, this means that the position is encoded as a series of 1's and 0's that are sent one after the other; "synchronous" means that the senderd (scale's reading head) and the receiver (EZ-View display or TouchDRO adapter) use a dedicated line that transmits the clock pulses.

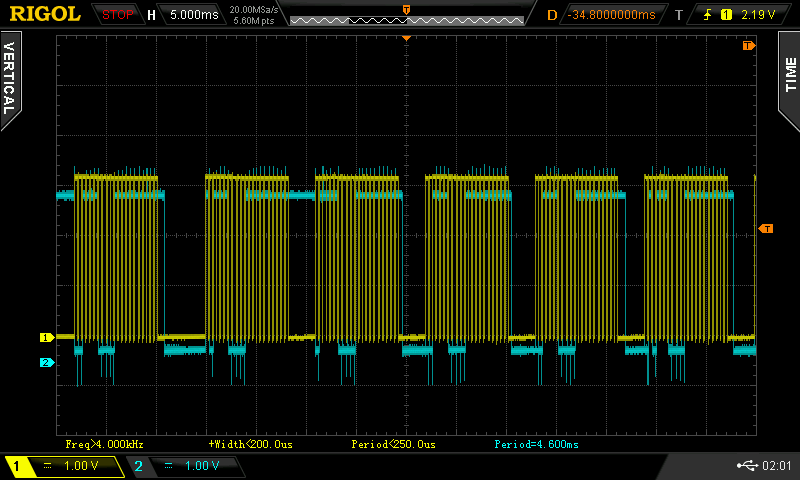

In the oscilloscope screenshot above, the yellow graph shows the clock signal and the blue graph shows the data signal. You will notice that the yellow graph has 21 equally-spaced bars, while the blue graph has a few large valleys (low reading) and plateaus (high reading). This works as follows: every time the yellow signal goes from high to low, the receiver samples the data line. If it reads a voltage below 0.3V or so, the value is read as 0; if it sees voltage over 2.7V, the value is read as 1. Internally, the reader puts these 0's and 1's together and converts the resulting number to a position readout.

Common Problems

Most iGaging EZ-View scale issues can be divided into the following four categories

- The sensor can be mis-reading the capacitance, which will throw off the position reading due to electrical noise, spurious capacitive coupling, or even metal swarf that gets between the encoder strip and the sensor PCB.

- There could be an issue with the scale's processor caused by excessive voltage fluctuations on the power supply lines, or there could be an internal fault or a manufacturing defect.

- A physical connection issue between the reading head and the DRO display or TouchDRO adapter can lead to data stream corruption. This can be a broken cable, cracked solder joint, or even a loose USB connector.

- Shop noise can cause spurious spikes in the data transmission. The receiver has no way to distinguish between legitimate pulses and noise, leading to momentary data corruption.

In practice, some of the above scenarios are more common than the others;, therefore, the list below covers the one that you are most likely to encounter.

Last Readout Digit Flicker

This is the most common complaint about iGaging scales. It manifests itself as a flickering last readout digit that changes up and down by 0.01mm or 0.0004" even though the scale is stationary.

Causes

This behavior is inherent to the scales and is caused by encoder interpolation error. In other words, if the reading head is stopped between two discrete encoder marks, the scale has to either round up or down. Since these particular scales determine their position by measuring minute changes in capacitance, minor changes in the supply line or unwanted capacitive coupling can influence the reading enough to "nudge" one way or another.

There is no good solution to this problem. The native display works around it by a combination of averaging several readings, rounding, and latching of the least significant digit. This approach has two huge drawbacks: it reduces the precision of the position readout and introduces lag, especially for very small movements.

TouchDRO application has an option to enable weighted averaging (called Digital Filter). The algorithm is different from the one used by iGaging, so it doesn't lose accuracy but is also less effective at eliminating the flicker.

Momentary Position Jumps

The position suddenly jumps to a random value and quickly returns to the correct reading. In some cases, this can happen only occasionally, but at times can be a constant nuisance.

Causes

Most commonly, this is caused by the scale incorrectly setting a random "low" data bit to a "high" value. On the scope, this looks like a well-formed square signal that just happens to be in the wrong place. The cause might be an internal logic glitch or a reaction to external noise, but almost all iGaging scales do this once in a while. For some reason, some scale specimens are more prone to this than others.

Another possibility is spurious noise in the data line that is interpreted by the TouchDRO adapter as a "1" instead of a "0". On the scope, this appears as a malformed spike that is different in shape and amplitude from valid data pulses. This scenario is very uncommon since noise is rarely isolated just to the data line and noise on both lines behaves very differently.

There is currently not a good solution for the first cause; the second cause can be addressed by shielding the scale cables and eliminating ground loops.

Permanent Position Jumps

The readout suddenly jumps to 0, a random position, and stays there as if the scale moved by that distance. More often than not, this happens when the motor is started or stopped.

This happens when the scale resets its readout to 0, but since at a given time TouchDRO can have various offsets applied internally, the resulting readout can be either 0 or a combination of the applied offsets.

Causes

The culprit is a sudden scale reset, usually caused by a momentary polarity reversal in the scale's power supply. Almost universally, these spikes are a result of long ground loops between the machine frame and TouchDRO's power supply. Please refer to Avoiding Common DRO Scale Problems for the steps you can take to address the issue.

This situation is very dangerous and can permanently damage the scale, so it's best to immediately power down the adapter and address the root cause.

Readout Jumps All Over The Place

- When the readout is continuously jumping to random positions up and down the axis, there are a few different variants of this behavior. So it's important to note the following:

- Does this happen only when the scale is moving or this happens regardless of whether or not it's moving or is stationary

- Does this happen only when a motor or VFD is switched on or continuously

- Does this happen to all scales

- Does plugging the affected scale(s) into a different input stop the problem

Causes

If only one scale is affected, in the vast majority of cases, the culprit is a bad connection that can be caused by a loose fitting in the Scale's USB connector, break inside the cable, or cracked/cold solder joint.

- Breaks in the cable and faulty connection inside the reading usually causes jumping when the scale is moving, but in some cases, it can happen when the scale is parked in a specific position. Plugging the scale into a different input usually doesn't affect the behavior, but jumping can change when the cable is moved or wiggles.

- Loose-fitting connection on the TouchDRO adapter usually affects only one input on the board. If moving the scale to a different input fixes the problem, this is most likely the problem.

The most common cause of the faulty connection is a cracked or cold solder joint. These are very hard to see, so the best fix is to apply some flux and reflow the joint. If you purchased a pre-assembled TouchDRO adapter, please email yuriy@touchdro.com to arrange a repair. Breaks in the cable or loose USB connectors are very uncommon and can be fixed by replacing the cable.

Occasionally, the wire connecting a small metal grounding strip inside the scale's head can break, which can cause erratic readings. Re-soldering the wire usually fixes the issue.

If more than one scale or TouchDRO adapter input are affected, the issue is most likely caused by excessive noise. In

most cases, this is caused by poor motor or VFD grounding and/or ground loops in the setup. Please refer to the

Readout Steadily Climbs

Even when the scale is stationary, the readout climbs up, often by an equal distance.

This issue was more common with older iGaging DigiMag scales, especially when used with the Arduino-based adapter. It is very rare with the newer scale revisions.

Causes

The cause of this behavior is not well understood, but the evidence points to it being a result of power supply noise and excessive current draw on the clock and data lines. There are a few common patterns:

- Older DigiMag scales were more prone to this issue, often when the machine motor was started. The issue was related to line noise and ground loops, and some people were able to fix this by isolating the scale's frame from the machine's body.

- In some cases, the scale's reading head was reversed on the scale frame, and rotating it end-for-end addressed the issue.

- Very rarely, a wire that connects the small grounding strip to the PCB inside the reading head can be broken; resoldering the wire fixes this issue